Forming Moulds

Tool making at GEISS AG began when the company was founded in 1948 and draws on more than 70 years of model and tool making experience. By today’s standards, the early thermoforming tools would be seen as simple; inserts for cutlery trays which were created by hand, whereas todays deep draw tool has few limits in terms of complexity. At Geiss AG, such tools are designed, using leading 3D CAD systems and produced on state of the art 5 axis milling machines. The use of pore free aluminium enables even the highest surface finish requirements to be achieved. For extremely large tools we use aluminium castings with a defined wall thickness and with Geiss’ manufacturing capabilities, there are almost no size limits.

Some examples of Geiss tools

- Refrigerator Doors, Liners and Trays

- Sanitaryware (eg. Bath Tubs, Shower Trays)

- Roof Boxes

- Technical Parts (Pallets, Airducts, Automotive Interior Panels, other Panels)

- Milling devices / Milling fixtures

Following the thermoforming process each part needs to be finished into its final form. Most often this is completed by trimming. Geiss’ tool making department can offer you a wide range of support with trimming fixtures made from aluminium or Ureol, as well as complex weld constructions with a wide variety of clamping systems, which can be the solution to many problems. Geiss have a wealth of experience in deep draw forming and know the associated difficulties, therefore they can identify and minimise problems in advance. The fact that GEISS supply from a single source is certainly of benefit. Parts formed on Geiss deep draw machines can also be finished on Geiss Trimming Machines.

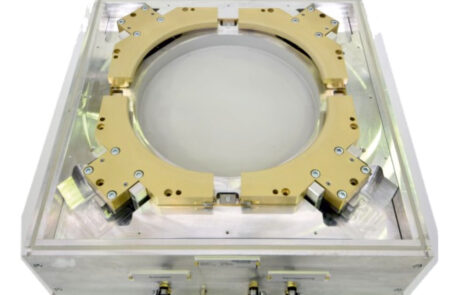

Jigs for Precision Trimming

For their Forming Moulds & Jig manufacture Geiss utilise CAD CAM Software Tebis.

Centre Console Fixture

Centre Console Fixture