Machine Servicing and Spare Parts

Swanstone has developed a full preventative maintenance program to ensure that each machine continues to run efficiently throughout its design life and to limit down-time. We are proud to have a longstanding team of experienced engineers and service support personnel at the disposal of our customers anywhere in the UK, Ireland and Europe.

The availability of spare parts, from our own stores as well as trading partners, enables us to offer the most comprehensive service possible.

Services Offered:

- Scheduled servicing and machine maintenance

- Breakdown assistance and fault finding

- Supply of spare parts (self-fit or fitted by our qualified engineers)

- On-site training courses (tailored to customer needs)

- On-site CNC programming and program optimisation

- Machine Safety Inspections

- Machine valuations

- Machine evaluation for refurbishment or PLC upgrade

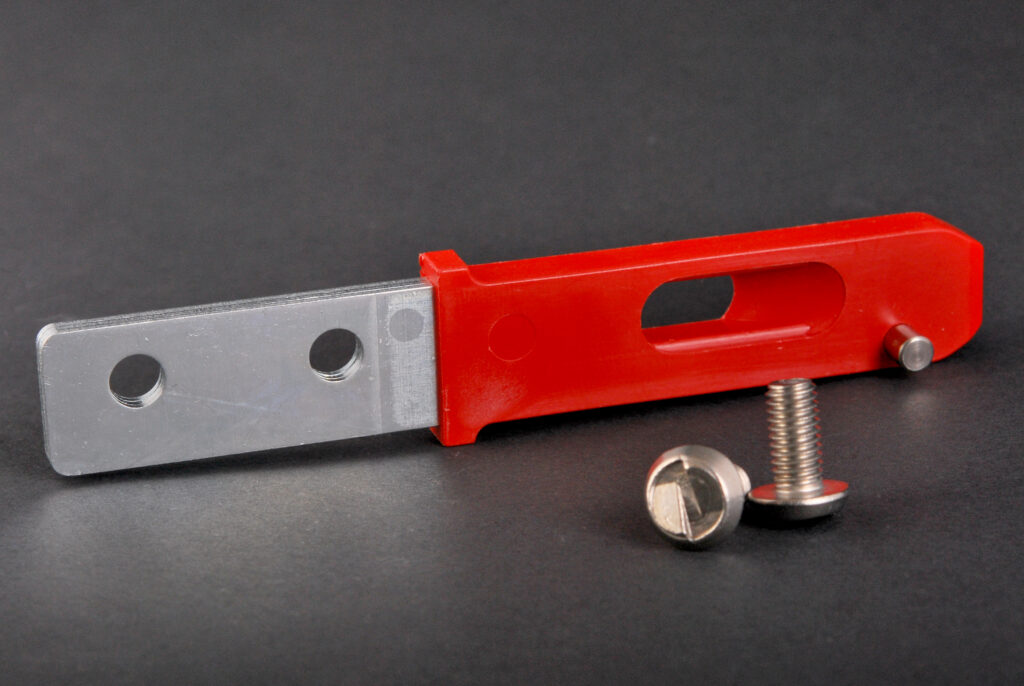

Spare Parts

At Swanstone we pride ourselves on the extensive range of spare parts and accessories we have built up and hold in stock. We carry a multitude of the most commonly used parts for our Vacuum Forming, Trimming and Blister Packing Machines. As well as the products held by us we have full back-up support from both Geiss and Tommy Nielsen, giving us access to 1,000s more components.

In addition to the latest generation machines, we are able to supply spare parts for older equipment and, where parts are obsolete, can assist in identifying suitable alternatives. Geiss and Tommy Nielsen also both manufacture many specialist products in-house, which offers greater flexibility on availability.

We regularly supply parts by next day delivery where other suppliers would normally quote longer lead times and have a multitude of shipment methods at our disposal, enabling us to meet our customer’s needs as efficiently and cost-effectively as possible.

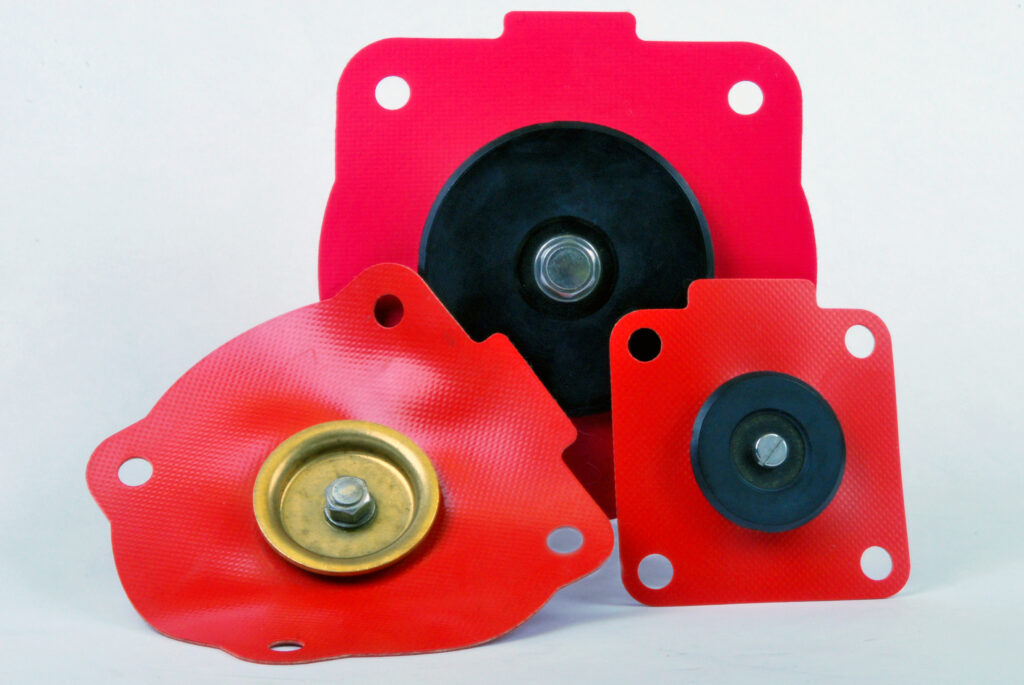

Carbide Cutting Tools & Abrasives

Our longstanding partnership with an industry-leading manufacturer enables us to offer efficient, cost-effective trimming and finishing solutions from a vast range of high quality Carbide Routers, Tungsten/Carbide Burs and Abrasive products. As well as ready-made solutions, our extensive experience and knowledge in the field, in conjunction with the manufacturer, gives us the ability to develop fully customised, made-to-order products.

In addition to the Routers, Burs and Abrasive products we also supply a range of high-end Air Tools to support these. Our extensive range provides a solution for the majority of grinding and finishing applications, offering increased efficiency, reliability and safety. All tools are manufactured to reduce injury through vibration, with specific Low Vibration equipment being available.

Cutting Tools

Cutting Tools

Quality of Supplied Products

- Our routers are solid carbide, made with the highest quality materials available, allowing us to offer a high-end product with optimum performance and increased lifespan

- Ideal for use with plastics, as well as composite materials, our versatile range of routers can be used with both hand-held tools as well as CNC trimming machines

- Burrs can be supplied coated, which considerably increases the efficiency and lifespan of the product. Coated products have reduced teeth wear, offering improved chip removal, resulting in less friction on the tool and an overall reduction in heat build-up

- Our large range of abrasive products are designed for use on a multitude of materials from steel, wood, plastic, paint and rust and can be used in conjunction with any appropriate hand-held tools

- The anti-vibration technology of our Air Tools reduces the risk of Hand-Arm Vibration Syndrome (HAVS), Vibration White Finger (VWF) and Work Related Upper Limb Disorder (WURLD) to the operator

- Maintenance packages, replacement spare parts and a full range of accessories are available for all Grinders and Sanders in our Air Tool range

- Full technical advice and back up support is available on all consumables and tools